Last week at Facades+ Chicago, organized by AN with long-established design and engineering firm SmithGroup, a roundtable brought together Bill Zahner, former CEO of innovative metal fabricator Zahner; Lauren Van Reken, senior preconstruction services manager at powerhouse curtain wall manufacturer Harmon; and Juanita Garcia, senior project manager at environmentally focused construction management firm Pepper Construction. The early part of the discussion was led by Garcia, and the Q&A session was moderated by Matt Dumich, principal at SmithGroup.

Before an audience of nearly 200, the speakers shared how their teams are working to reduce embodied carbon while responding to tariffs, how manufacturing facilities are cutting waste and improving recyclability, and how new workflows play a crucial role in achieving design excellence. The following is an excerpt from the conversation.

Juanita Garcia (JG): Let’s start with the current state of the industry. Have you seen a growing demand for sustainable materials, and if so, what challenges stand in the way?

Bill Zahner (BZ): Yes, and metals are often at the center of that conversation. Metals are the only construction material that can be recycled endlessly without losing its properties. The initial production carries a high embodied carbon cost, but once in circulation, the impact drops. For aluminum, recycling uses about 95 percent less energy than producing it new. There’s also a strong recycling infrastructure. I often say that not a square centimeter of copper at the de Young Museum in San Francisco will ever end up in a landfill.

Lauren Van Reken (LVR): Architects are definitely paying more attention to sustainability. A major shift in the last five years has been the rise of EPDs (Environmental Product Declarations), which measure the life cycle of materials. Overall, some of the larger vendors are ahead of the curve on EPDs; they have the resources and data to provide full life-cycle information. But when tariffs push us toward smaller, domestic vendors, many of them struggle to produce accurate EPDs, which sometimes means bringing consultants on board to complete them correctly.

BZ: I’ll add that accuracy is critical. Too often the information within EPDs lacks clarity, which makes it harder for designers to rely on them. My hope is that architects and designers dig deeper into the data to really understand what’s being presented.

JG: Could you share more about innovations in your organizations?

BZ: In our plants, all the lighting has been converted to LED, and we’re monitoring peak energy times to manage machine use. Small changes like that add up when the lights are on 24/7. Another shift is in how we treat metals. Ten years ago, our patination process produced 160,000 gallons of wastewater a year that had to be hauled away. With reverse ionization, that has been reduced to just 28 pounds of solid waste, which we recycle. The water is reused in-house. It saves money, eliminates trucking, and was recognized by the EPA in Texas.

LVR: At Harmon, we’ve tested robotics for field layout and anchor installation, and I think in the near future we’ll see autonomous scanners marking stud walls and anchors on job sites. In manufacturing, robotic glazing machines and advanced CNCs are already automating drilling, cutting, and even loading parts without people touching them.

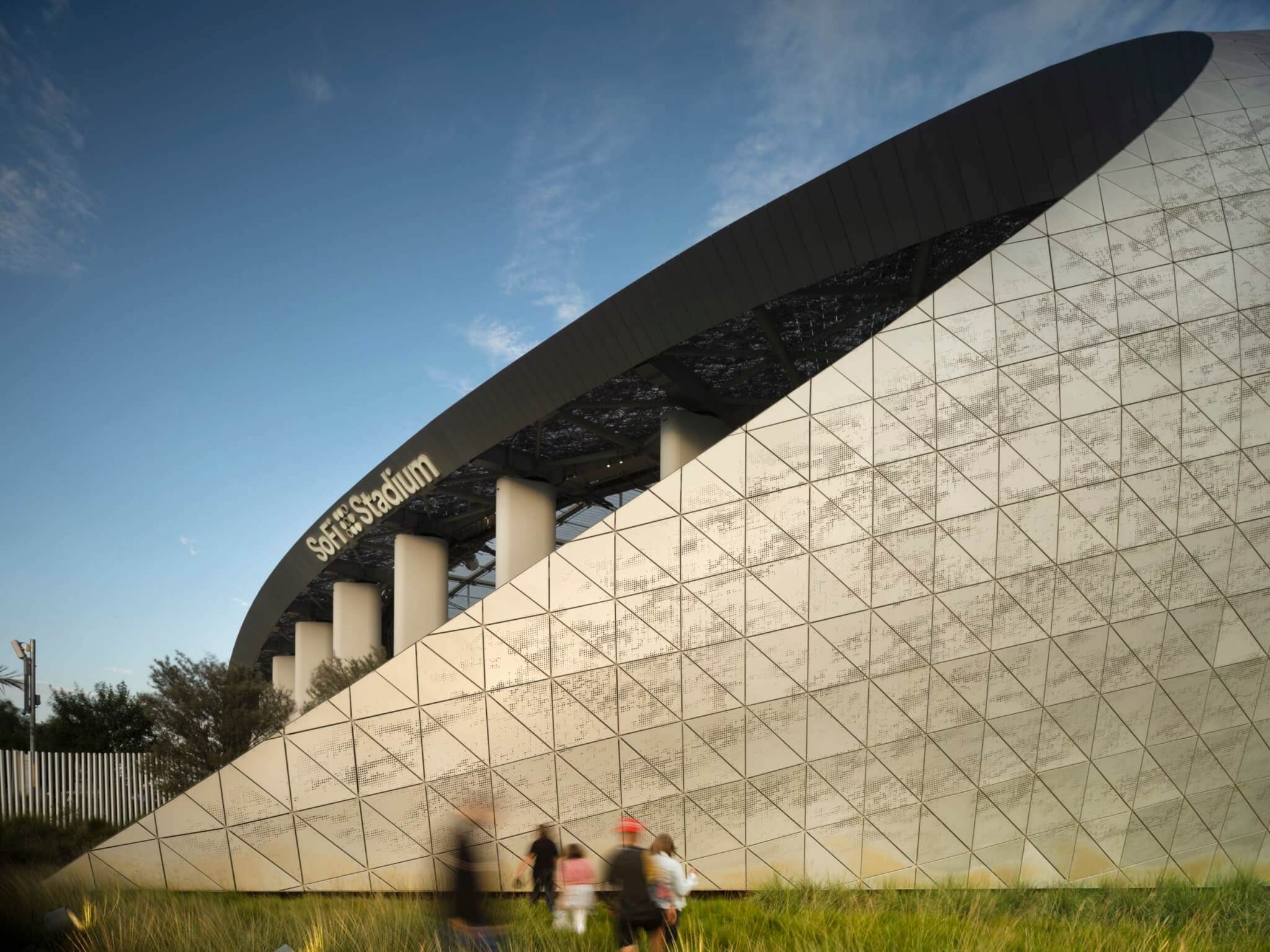

BZ: Packaging is another area. Job sites produce enormous amounts of waste just from shipping materials. At SoFi Stadium, we shipped components in reusable “pizza box” containers that were broken down, palletized, sent back, and recycled. We’re also looking for alternatives to protective films like Nitto, which can last for centuries in landfills.

JG: Can you share a recent sustainability win from collaboration?

LVR: In recladding Northwestern Mutual in Milwaukee, the old facade was removed and reshaped to match the adjacent tower, and nearly all the stripped material was recycled. It shows how we can work with buildings that have good bones—making them more energy efficient, upgrading the glass, and meeting higher thermal performance standards without tearing them down.

BZ: I also want to recognize architects for pushing sustainability. Producers are listening. For example, a new nickel mine in Canada is being designed to operate carbon-negative by crushing olivine, which captures carbon during processing. Five years ago, no one in the industry was talking about this. Now the conversation is everywhere, and that’s exciting.

Matt Dumich (MD): Thank you, Juanita, for moderating. I’ll take over so you can join the audience Q&A. The first question from our audience is: How is your company approaching circular construction?

JG: At Pepper Construction, we’ve been looking at demolition materials and extended producer responsibility. We’re piloting this for one of our own offices, and if it works, we can scale it elsewhere.

BZ: Metals have always been recycled, but now we’re also sorting paper, wood, and other materials. We can also request higher recycled content from suppliers.

MD: How is the landscape of suppliers changing in North America?

LVR: It’s really developer dependent. Now, facing tariffs, some still want European products and are willing to pay for them, while others want to stick with North American vendors.

BZ: Metal production in the U.S. has been limited, but companies like Nucor are stepping up. Prices rose when tariffs hit, so we’ve explored ways to offset costs, like reducing thicknesses or changing fabrication approaches. It’s still something that needs to work its way through. In design-assist, we work closely with architects to manage costs. Copper alloys, for instance, are up nearly 30 percent, so we look for other savings to balance things out.

JG: Tariffs can also make us look at reclaimed or domestic materials instead of imports. It is important to consider that transportation itself is part of the embodied carbon story.

MD: What has changed about project delivery methods in the last five to ten years?

BZ: Digital modeling has been a big shift. We use small and large prototypes so clients know exactly what they’ll get, which eliminates surprises.

LVR: Early BIM models are very helpful, and now 3D printing lets teams test how parts will connect. The technology is not perfect, but it goes a long way in figuring things out.

JG: Yes, and with life cycle assessment tools like One Click LCA, tied to BIM models, we can identify the most impactful materials early and focus on reductions where they matter most.

MD: What makes you hopeful about the industry?

LVR: Even simple tools like GoPros on hard hats can give us better insight into job sites—more useful than webcams—for punch lists, facades, and MEP coordination.

BZ: AI is starting to shape packaging, fabrication, and installation. It won’t replace good design, but it will support it. I’m also hopeful about the next generation—there’s a lot of sharp young people entering the industry.

JG: I agree. AI and better data will help us design and build smarter, with more transparency around impacts, which can help improve the built environment for everyone.

→ Continue reading at The Architect's Newspaper